DIGITAL AUTOMATIC MANAGEMENT OF GRAPHIC INDUSTRY PRODUCTION WORKFLOWS

Petar Miljković

Summary

Digital management of graphic industry executive process creates prerequisites for a remote control of all the stages of production, the phases of execution. The development steps of extensible compatible external units to be integrated into flow-chart, that makes the workflow of production processes; create a certain constant in graphic communication. Structural modulation in the exchange of information, respectively, its functionality, reflects in the network connections of all the production entities (prepress-press-postpress) with the timely distribution of code records to all the management subjects. The new method of workflow distribution in graphic communication systems requests specific organisation approaches as well as a different ways of thinking.

Newly-created managing algorithms are enabled to issue commands to executing mechanisms. In such method of conducting the graphic production processes, a basis of the flow-sheets is created that are enabled to manage the jobs for each and every individual graphic product.

The elementary Directive of International Consortium CIP4 was in the standardisation of the future situation and has created a prerequisite for the introduction of a new unique code record in the form of a JDF record.

Key Words: Workflow, automation, digital integration, JDF, XML

1. Workflow by means of network communication

The development of graphic industry is in a direct dependence of the development of information technology as well as its support in the processes of the communication within production departments. To put it concrete, with the graphic industry, integration of informatics has not been presented as an evolution in a digital world; it was a revolution. In many aspects, printers do not keep up with modern industries (e.g. robotization in automobile industry) and only during some recent ten years, some more significant congresses with the topic of "Digital Smart Factory Forum” have been kept. The progress of printing companies is reflected most in creating automation in the transfer of digital records from a preparation department (or marketing) to the departments of print and especially to the departments of finishing (or at the shipping department, in the form of personalisation).

Digital communication is presented at the relation of prepress press postpress at the instructions of the Consortium of CIP3. With that instruction, however, the description of supervision and control of the very process execution model, and the way in which communication is carried out is missing. An addition has been therefore issued in the form of CIP4 record (not meaning that CIP3/PPF stopped being in force) that describes it. The change in communication that is carried out within production departments in the form of the network communication base on Internet connections (or Intranet) has been provided thanks to a new marker code record of XML, all being within JDF communication. Network technology supports the transfer of information also at different control platforms what is especial advantage as all the departments are not equally automated. Mutual integration of operational units in vertical way of communication is enabled thanks to a quick development of program applications for individual stages of operation. The development of the database that is necessary for further progress and creation of standardized production through relational or hierarchic integrations provides for the structured SQL language that represents the organisation to the order issuer (user of records). The organizational structure of the data is based on a subjective idea of a foreseen case and not on the way how to come to wished-for information. The order issuing information to production departments directed by the production manager have the need to realise a connection within production resources in the form of vertical integration system. In modern printing plants, such communication is expressed in the form of JMF orders. Horizontal communication refers to the integration within operational execution stages at the different execution positions.

The purpose of every successful operation is the recognition and implementation of all the prerequisites that will offer an energetic response to the requests put before graphic industry as a whole. The basic approach in the programming of the way of communication can be expressed through the procedural paradigm. The programming is approached in that way as a logical sequence of the instructions that, in the proposed way, control the information aspire after resolving a set task. The specified variables are created for a location position in a computer, where the programs recognise the written code more clearly and use it. The variable, as a small data-basis, uses the executive instructions to store the information and use it.

With the development of the new program for integration, it is necessary to approach in line with the sequence of events in the processes of production:

• the issue of communication is to be presented and its workflow of events understood;

• an algorithm to be made as a final sequence of instructions with a clear functional meaning (realisation of the questions put);

• executive program is to be prepared (no finished “plug & play” solutions exist), with the specificities of each printing plant individually (attention should be paid to the clearness of proposed situations and correct executive specification of equipment);

• testing of finished program and its parallel work with the mode of management up-till-now;

• all the changes are to be recorded and corrected subsequently (creation of a data base);

• education of employees and their permanent improvement.

The integration of informatics opens in a certain sense the possibilities for the management of the control processes through the computer from the production manager’s office as well as for the creation a data base wit input parameters. The development of modular units, which transfer information to executive operative functions are in a permanent development aspiring after a unique production process with the possibility of a permanent annexing.

XML as a code communication system that is a base of the whole JDF communication integrates application systems and standardises printing variables. As an imperative of development, a need is proposed for a comprehensive Internet communication within production entities with a complete XML-isation. It is necessary to establish production standards and form the own printing dictionary as a basis for communication.

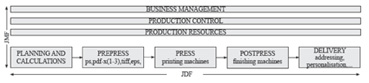

The new format of the graphic communication of JDF provides for network connection with the purpose of procedural and digitally automated procedure at the exchange of information between the program and a printing machine. The control of the very procedure in the creation of a new operating logic accelerates operative processes and individual phases obtain another dimension in the integrating of the whole production process of graphic industry. Communication technology, arising from the management module implements development attributes at the organisation of new and more profitable production flows, what offers a reply to the requirement of administrative departments. Their filing and subsequent analysis are provided. In the very production communication, two basic directives of the flow of information are differed with respect to their intention. Managerial information connects production resources in the form of a vertical systemic integration while horizontal communication connects working operations in their executive phases (figure 1).

Figure 1: Vertical and horizontal communication

With the further development of JDF at the standardisation of graphic industrial production, the prerequisites are provided for a possible implementation of computers by means of what semiautomatic way of control is abandoned and CIM takes over its function in the full sense. Information system completely integrates all the production plants and it is in an interactive connection with a company’s management. The architecture of the management is designed in a way to provide for a timely exchange of information at any moment. The production that is so integrated production includes in its executive function two levels of management; technical and organisational-administrative ones. The next division refers to the production planning and its execution.

To each of assigned tasks, the attributes should be added to identify its status in production cycle and to define the directives in the further exchange of information. Process automation and the standardisation of graphic executive flows, including also the flow of digital records, are presented according to the stages:

• information flow from a client to finishing and delivery is enabled;

• a complete control of all production processes is secured;

• subsequent corrections and changes are enabled in the very process of production flow;

• bottlenecks are avoided at the work stages or re-directing of information is performed to a new production planning as well as also the individualisation of each working post with a precise description of working tasks is made;

• the creation of bases and models of production is enabled as a starting point for its automation.

Production planning and its realisation with its control in executive departments of a printing plant are entirely integrated into MIS, as new vertical management information. The basic goals of management can be presented as:

• the use of JDF that is “installed” at the intranet (or Internet) as a basic network provider within production departments, respectively in the language of graphic communication for each product to which production elements have been added;

• besides automation of production flows, it is necessary to present to the management also the way of optimisation of workflows with the emphasis on the integration of the processes and the integration of external subcontractors;

• technical support and controlling;

• the request of a client that is to be transformed into the possibility of printing plants and its permanent interaction with possible changes and subsequent tasks.

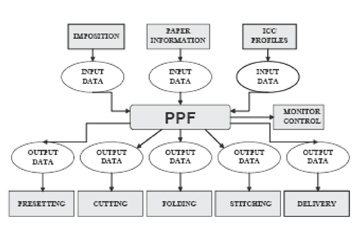

MIS is in charge for efficient realisation of production as it integrates all the production possibilities of particular machines to be installed at the departments of a printing plant. Through such integration, the inflow of all the information from workflows, to be supplemented at the data base, and the parallel control of existing information for the same product is also enabled. The record of MIS that is relied on the open and upgradeable architecture transforms the jobs into coded time events (records). The architecture of operations is conceived through operating nodes to which each and every operative stage is associated and they themselves are composed as a structural pyramid. Information flow is developed vertically and horizontally and only such a composed bitmap image of code records provides for timely informing of all the participants in operating process at the same product (figure 2).

The jobs integrated by MIS and necessary for continuous productions are:

• advance planning of operative process (technologic preparation) and the presentation of a workflow diagram;

• presentation of a structural pyramid with necessary operative nodes marked, including the existing warehousing resources and delivery of finished products;

• information transfer and comparison of the same with the database;

• communication with the client to have ordered the products and his insight into the total operative process;

• flexible adjustability for all unexpected situations (possibility of alternatives);

• information transfer after a finished job according the technologic preparation of operations and the connection with accounting department;

• subsequent data processing after finished working process and its statistical reports.

Figure 2: CIP3/PPF as a concept of input and output information relations

Present graphic industry is entirely adjusted to the requirements of digital integration so that the control units of modern printing machines are directly connected with MIS systems through JDF introducing the job files and transforming them into the usable information for the working consoles of the same machines. Each record is adjusted to individual control console according to various control platforms. The information for a job is available on the console at the moment when the technologic department performs preparation with the description and by means of network integration, passes the same to prepress unit. Further sequence of information to the press department is executed without additional data recording, by means of which every possibility of the wrong interpretation of a job is avoided. The final executive information is available on the working console and it is filed and confirmed at both sides. Besides the information about the product, the job can contain also CIP3 information on the pre-adjustment of printing machine. Such a form of communication requires prerequisites in the form of a business system providing such degree of information. It is important to emphasise that each flow of information into the direction of press requires from the preparation units also a reversible procedure. The return information is of the same importance for further communication to the client. In the most of the cases, such an information is not always timely available and sometimes it is late and when its meaning is questionable in the total process of production.

2. Application of codes with CIP3/ppf information exchange

CIP3 format finds its standpoint in a PostScript format with the purpose of the interpretation of the attribute for the execution of preparatory phases on a printing machine as well as on the finishing machines. Mutual connecting with the data exchanges concerning a graphic product are transformed to command definitions describing the work jobs. Information input is provided from two aspects: as an input parameter for a particular machine aggregate or as common information with the description of operative functions. Recorded predispositions to be defined according to recorded situations are classified into several subgroups:

• basic information about reproduction material and required quantities calculated according to each working machine;

• provided filing of transfer curves in the coordinate system (a position on a film if there is no CTP, and the position of coordinates at the board);

• description of finishing stages, or a position of marking for sheet trimming, folding and binding. After the finishing job, distribution list is described.

CIP3 (founding of international foundation in February 1995), based on a PPF format achieved its purpose due to a variety of code records to have existed in practice at that moment. With the parameters generated in the mentioned code records, the carriers of starting information are created with their record being non-unified. The profession requested a need to apply the proposed standards. Such non-standardised approach in various digital forms, as input information, is an aggravating circumstance for further production processes. Mutual digital lack of connection of graphic machines is of no crucial significance as the transfer of information in PPF record can be realised also by individual approach to each machine that is equipped for the accept of digital records. Such a communication can also provide for a digital base of working orders as well as the creation of digital flow-charts of all the workflows. The use of these records in the next jobs is a great help at the creation of savings in work time and reproduction material, by means of what the competitiveness is secured at the market.

3. Coordinate systems in CIP3/ppf information exchange

Allocations and presentations of the items present on the equipment participating in the preparation of information are defined according to the rule of sliding pairs. A differing pair of real numbers placed on x and y coordinates position the measuring item horizontally and vertically at a relevant space as for a film (if they are still applied) and equally, for the offset board. The information of original issuing locations are recorded (or some other set points) of the measurement template as well as the position of each specific point positioned within the system. By means of PDF record, it is possible to define some more space of the measurement for a graphic product in production. The transfer of information in the form of graphic or textual record is transferred by means of the PostScript language of communication due to its open architecture and the own stability. However the PS itself showed to be a problematic record due to its size and impossibility of a check at all the working units.

The definition of measurement points of coordination system starts with the choice of real numbers at the axis of x and y within a defined measured space. The original position is the first to be marked, or its place within the xy axis and the length of each unit positioned within the space to be measured. The measured parameters respectively the basic ones, to define the transformation within ideal coordinated axes of x-film and y-film and the measurement coordinates xd and yd are:

x-y centre position of measurement template or a direct carrier of the tone value of raster;

„w_c“ (raster angle between “xf” and “xd”)

„K“ factor of the measurement scale for the correction of a raster and template deformity in coordinate system “c” to “f”.

The transfer of information in the mentioned two coordinate spaces is carried out with the present deviation as shown by the following formula:

xd = x_cen + K*(xf*cos(w_c) - yf*sin(w_c) ) *mm_rast_x

yd = y_cen + K*(xf*sin(w_c) + yf*cos(w_c) ) *mm_rast_y

Due to differences in a system, it is necessary to execute transformation within them with the possibility of accepting the differences. The mentioned way of transformation requires the use of matrixes for the description of two-dimensional coordinate system P=(x,y) to be subsequently presented in a vector record [ x y 1 ], where the number "1" presents certain action as e.g. scaling, rotation or translation. Matrixes are presented in the form of 2 x 3 but it is in practice, though, a more usual form of 3 x 3.

![]()

In PostScript program language, the digit “1” would be omitted and matrix record presented as [a b c d e f ]. Beside graphic preparation and printing to be executed by means of so recorded printing offset boards (instructions for the pre-setting of the machine are directed by means of PressLink connections) a finishing phase follows respectively the preparations of the sheets for binding. At the rotation machines, it is possible to finish in “one passage” a just imprinted a roto-sheet of paper that is folded into a finished non-trimmed format. The information to be sent to a control unit (e.g. PECOM device at MAN-Roland machines) is sent by ManagementLink connections that are contained in CIP3/PPF document. The process of folding is defined and described as a PostScript record which contains parameters and methods of execution.

The example of bending with the commands for the format 880 x 610 mm (16 pp) onto format 210 x 297 mm in CIP3 protocol:

CIP3BeginingFoldProcedures

/A4-16 «

/CIP3FoldDescription (F16/3W \ (1/4\) + 1 ML)

/CIP3FoldSheetIn [880 mm 610 mm]

/CIP3FoldProc

[

220 mm 305 mm 660 mm 0 /Top Lime

220 mm /Front /Up Fold % origin moves right

220 mm /Front /Up Fold % origin moves right

220 mm /Front /Up Fold % origin moves right

0 mm 8 mm 220 mm 0 /Top Cut % origin moves right

0 mm 594 mm 220 mm 0 / Top Cut

297 mm /Left /Up Fold % origin moves up

5 mm 0 mm 0 297 mm /Top Cut % origin moves right

210 mm 0 mm 0 297 mm /Top Cut

]

« def

CIP3EndFoldProcedures

4. JDF information carriers within nodal networking

Achievable communications within the graphic industry and their integration through JDF protocol can be presented through three primary characteristics:

JDF expressed as XML code mechanism for information exchange to be associated with different information systems as well as the integration of the graphic equipment of various generations;

Information flow through the subsystem providing for the communication within the whole system of operation for each client information station where the control is performed;

Ability of implementing documents describing each necessary resource for completing the total printing stage of operation.

At the operating sequence of JDF performed e.g. to newspaper rotations, the automated control system performs checking (of previously recorded parameters) of the paper to be placed on the “star” of the machine for input and control of the paint in the tanks. Besides checking of reproduction material, a pre-checking of the whole machine is performed, or its set-up for the precision of the pulling a paper running through the machine (control of gas chambers, so-called drying chambers; control of cutting and subsequent bending of a paper tape; control of spinal sub-pasting; control of “coupling” etc.) and its tightness. The checking is momentary and all the parameters are received by JDF document from a central computer that controls the sequence of operation and the control is performed at the central control console. The flow of information through JDF is carried out by means of “nodes” that form a hierarchic pyramid. The base of the pyramid is made of more simple information about the product; describing its individuality as compared with the process of production. By means of moving towards the top, their execution is specialised to be made narrower, i.e. the processes are described that are necessary for its execution. At the very top of the pyramid, there are the information about the product and its connections with the client. Operational worksheet moves from the top downwards from where it is branched in a delta form. The processes of production are described by means of the nodes through all the stages of work including also the finishing of the whole production process with all its technical characteristics.

Three node forms have been in use:

• Product nodes (describing information and intention of a job);

• Process group nodes (describing the groups, i.e. production stages);

• Individual Process nodes (describing individual approach to a particular phase of operation.

From a node position, it is figuratively presented in which production phase is the observed product and all further functions directed to the finalisation of the product. At the nodes, the additional stages of operation can be annexed that form then certain sub-groups of the primary phase. Job description is printed in XML technology with a precise momentary situation. The relation between nodes can be categorised in two groups: hierarchically (vertical) and laterally (horizontal). By means of such an organization and node connection allocation, the main and auxiliary carriers of information are created. Lateral structure of JDF node brings the flow of information presented and it is in a permanent contact with resource capacities. The result of such connection is a transformation as a result of input and output information. The combination of horizontally and vertically set nodes creates a network of a communication with the intent of a faster and more profitable production.

Output information of a node is mostly the input information of the next one, where the process and resource records are exchanged. However, in simpler situations, JDF document is shown as one node where a function of the carrier of a certain segment of production is described (preparation, printing, finishing). Besides the basic characteristic data about a product and working stage, the acceptance of “subsidiary” data as e.g. data on the remaining position at the warehouse of reproduction material or information on a buyer is secured.

Besides constant and unified workflows of certain production stages, commercial manager, not-knowing all the process details and subsequent correction within a production process, approaches to JDF nodes creation from the top of pyramid to the requests set by the market. The top-level nodes are created that have symbolic attributes concerning a product image. They do not describe any process of production nor describe the types of reproduction material. The next stage with the creation of a nodular tree (pyramid) is association with existing nodes of a lower order, describing the details of a process, where technical staff is included describing all the specific stages of operation. The described nodes represent the least working unit with the production planning. Within a production node, describing printing, there are also the priorities of printing at the span between 100 (as the top level) to 1 (as the last at the priority). The attribute of priority i.e. sequence of printing is ascribed to each job. A current situation about JDF nodes can be presented on web pages of the printing plants as a guideline of the development and communication at both sides, between the clients and executors. Each piece of information to be distributed within production stages is memorised within a JDF protocol and it is therefore, as an independent record, available for other systems. The inputs of systemic data are automatically recorded and controlled and they are used for finding information about a product. Managerial supervision and control of the system can be performed at any networked working station. With a full integration of JDF protocol, all the processes will be presented transparently at both the directions of production, securing a safer execution with a more exact cost control.

5. XML structure and its application in information exchange

Some ten years ago, with emergence of XML marker language, the prerequisites are created for a digital age in printing industry. The date exchange was enabled among operatively different platforms and different data bases. A complete integration of whole documentation about a graphic product to for it foreseen systems has been enabled and their management in further work. A created record is possible to interpret in several ways, i.e. it is prepared for different ways of use (presentation on a computer screen, output units of lighting, printing machine, multimedia, etc.). A record can be issued from any computer from a text editor in a domicile language, defining the structure of data and not their definition of outlook. The XML tag structure is strictly defined in spite of the arbitrary character of XML, by means of what the further development of a document interpreting and editing is enabled. Each printing plant can develop the own language, adjusted to its specific needs what depends on its execution possibilities. XML has been developed for web communication in the first place, what simultaneously sets and requests the printer to perform his communication at the Internet and not at a local networking.

6. Conclusion

Integration process is manifested to production departments as an important link in securing a production process. Implementation of the idea at the organisation of managing and information transfer greatly depends on the idea necessary for its development. A prerequisite for a successful network project of communication is development in step-by-step modules as starting points for the preparation of organisation structure and parallel management in transience. Only a firm having technical and organisational prerequisites to realise a network integration can undertake further development and implementation. A network potential has great varieties and there is no universal solution therefore. Interfaces at the installed resources do not exist in all the cases and a question imposes therefore concerning their profitability with subsequent investments. There are no finished solutions in the form of “plug and play” systems that would be applicable for the most of printing plants, what could optimise the proposed solutions and completed the integration at different management platforms. In such complex situations, general algorithms are not accepted for production optimisation, but each production group (prepress-press-postpress or even also to sub-groups) is approached in an individually specific way, assigning to it specialised algorithms. A special attention should be paid to a prepress unit as it is often a key factor of success in the whole JDF architecture.

Present aspiration after total automation of production processes is expressed in the development of intelligent algorithms to integrate all the operational stages, but for present, there are not yet a finished solutions except for some individual attempts.